What is Charcuterie?

Whether you call it a tasting plate, grazing board, party platter, or charcuterie board - it's all about the flavour! Charcuterie (Shar-coot-ery) is the art of preparing, creating and arranging tempting salamis, delicious cured meats and delectable bites of perfectly paired cheese, antipasto and fresh fruit. What started as a way to preserve meat before refrigeration was invented has led to a platter of flavour.

Inspiration starts here

Start discovering. Find recipes bursting with flavour. Create the perfect charcuterie board with our revolutionary charcuterie builder. Even try salami origami for the ultimate presentation. Elevate entertaining with simple tips and new ideas!

Experience the flavours of Europe

Our sumptuous salamis and cured meats are made in the European tradition. Our sausages, hot dogs and meats are loved across Australia. Share a passion that goes back 60 years.

Our Products

Featured recipes

Mini Gourmet Pizza Combos

Open your own mini pizzeria with irresistible flavour combinations.

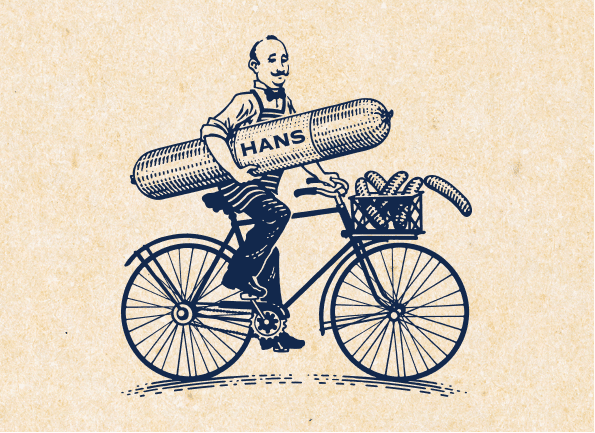

Our story

Creating authentic smallgoods

If there’s one thing Hans never compromised on, it’s flavour!

Since 1960 Hans has been delivering the most flavourful salamis & mouth- watering cured meats to the people of Australia. This commitment to European culinary traditions, combined with an unrelenting obsession for delicious flavour combinations is as strong as ever.

We deliver the best flavour, so you can deliver the best to your family, your guests, or just to enjoy all to yourself. You can taste our passion for flavour in every bite.